Information turboaggregat

Oljeläckage :

The Turbocharger Oil and Gas Sealing System

Many instances of oil leakage are wrongly blamed on a perfectly functioning turbo. Understanding how the sealing system works helps greatly in diagnosing possible root causes on the vehicle and will minimize wasted workshop time. Turbocharger System Diagnostics Guide may help you through the process.

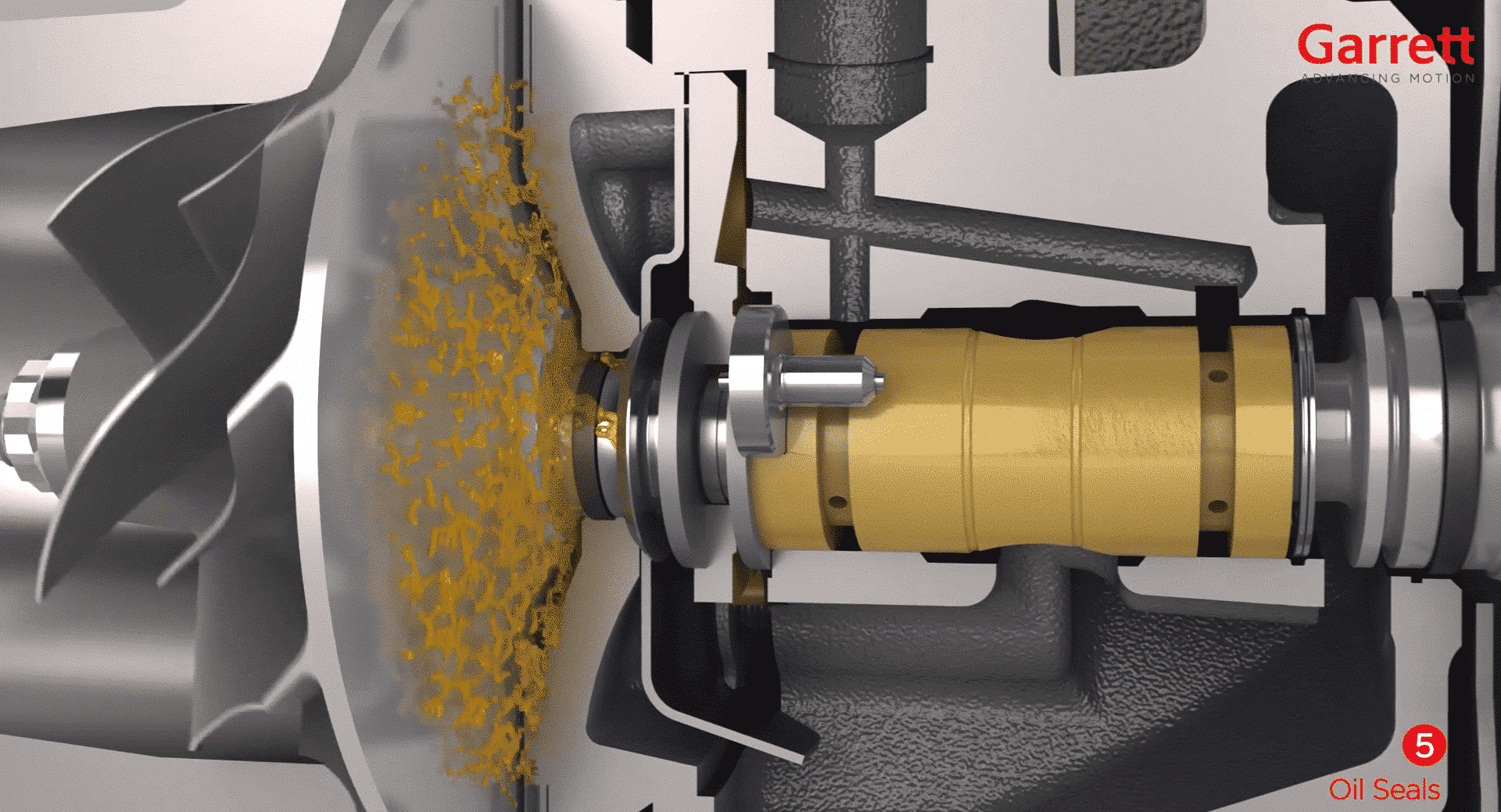

The Oil Seals

Vehicles and engines use a variety of oil seals. The most common of these is the lip type contact seal, which are highly effective, working with rotating shafts like the crankshaft. If one of these starts to leak, it is relatively easy to diagnose and rectify the problem, by replacing the seal. A turbo does not use this type of seal, due to the high speed, extremely high temperatures and the large shaft clearances necessary for correct operation. If oil is found to be leaking from a turbo, firstly it is more complex to diagnose correctly and secondly there is no possibility to just change a seal, like on a crankshaft. Changing the turbo may not cure the problem, as the oil leak is very often just a symptom of some other problem on the vehicle.

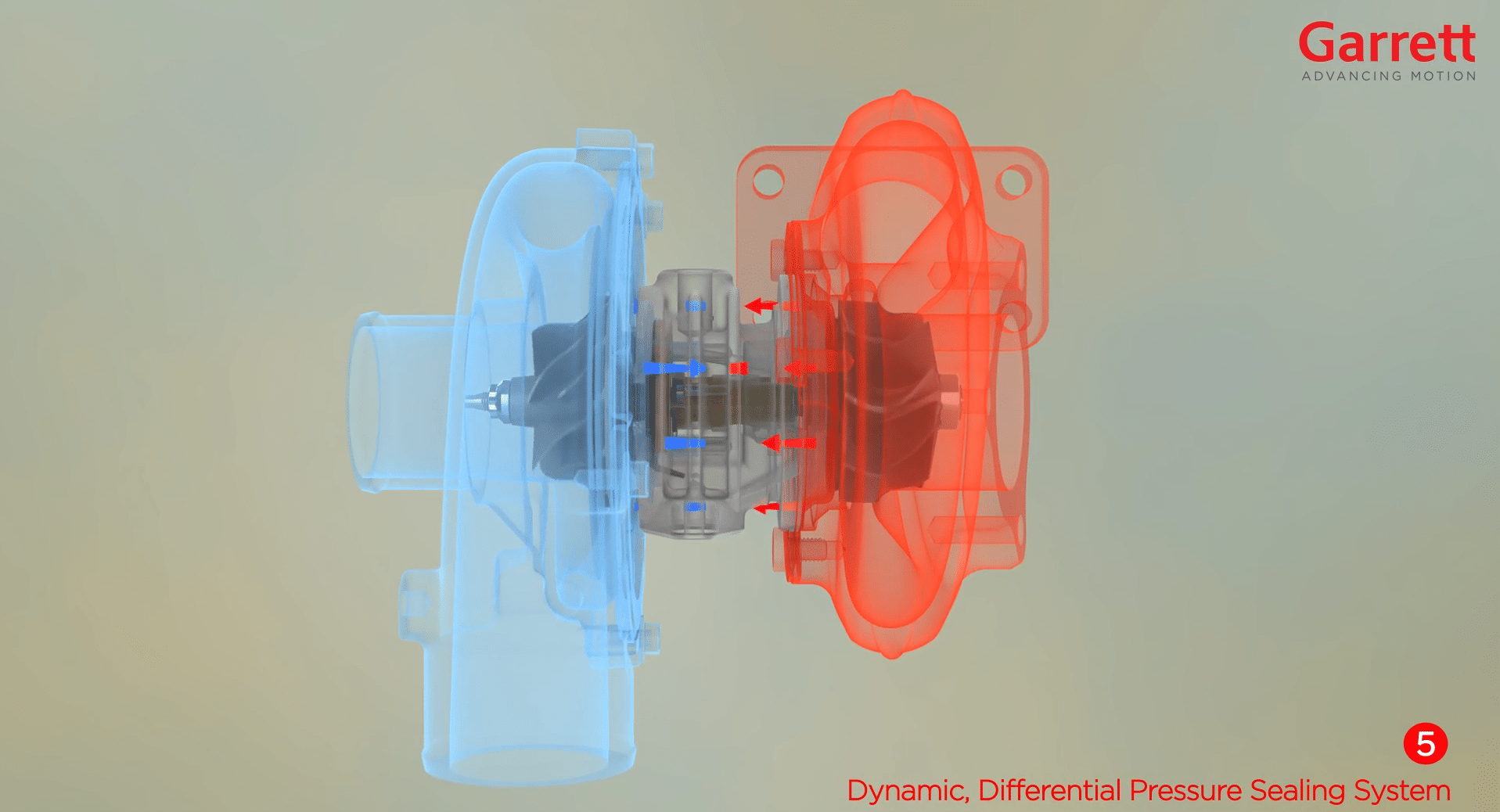

Dynamic, Differential Pressure Sealing System

Turbochargers use a dynamic, differential pressure sealing system. Dynamic, because it utilizes the rotation of the shaft and differential pressure because it takes advantage of the normal pressure differences between the three housings of the turbo: under most running conditions, the pressure in the turbine housing is higher than the center housing and the pressure in the compressor housing is higher than the center housing.

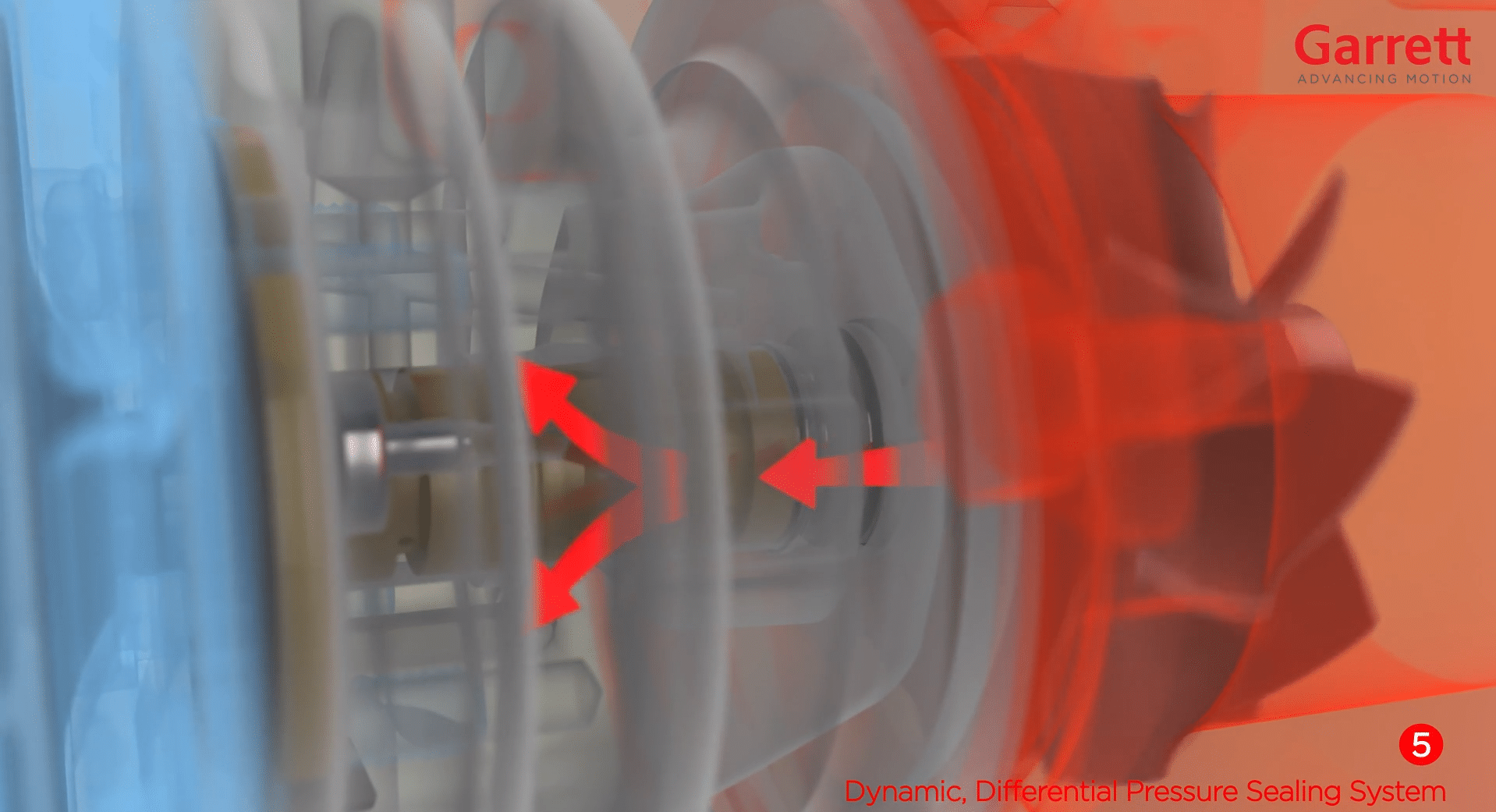

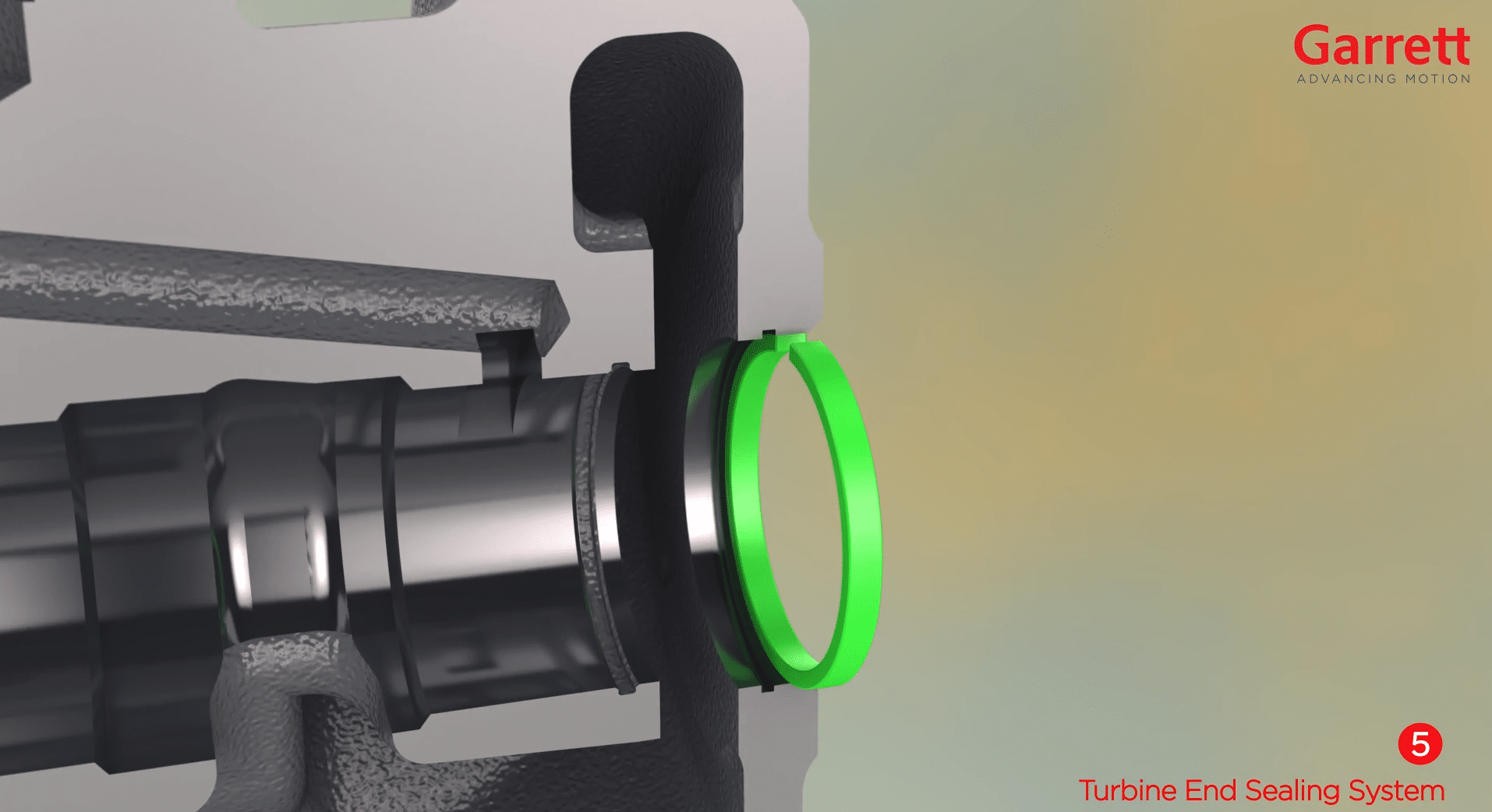

Turbine End Sealing System

At the turbine end, the sealing system is simple. After the oil has finished its work in the bearings, it travels along the shaft until it reaches the hub, where the spinning oil thrower literally throws the oil outwards by centrifugal force and it meets the inside face of the center housing where it drops down under gravity to be collected by the oil drain and returned to the engine sump. In addition to that, one or two piston rings are used which fit into a very accurately machined “stepped bore”. Unlike the piston rings inside the engine cylinders, these piston rings do not move. During the assembly process, the piston rings are compressed and once they are correctly located, the piston ring never changes position.

A natural feature of any piston ring is that it can never be a 100% seal, because there must be a running clearance at the two ends, plus clearances all around the rectangular section of the ring. However, in the turbo, this natural feature is used to advantage as some of the high-pressure exhaust gas from the turbine inlet passes behind the turbine wheel head to provide a very effective pressurized seal around the piston ring, to prevent any oil from passing out of the center housing. The tightly controlled piston ring clearances allow a very small flow of exhaust gas to pass from the turbine housing into the center housing, further helping to keep the oil where it should be. On some turbos, we may use bleed holes in the heat shroud to further increase the pressure in the piston ring area.

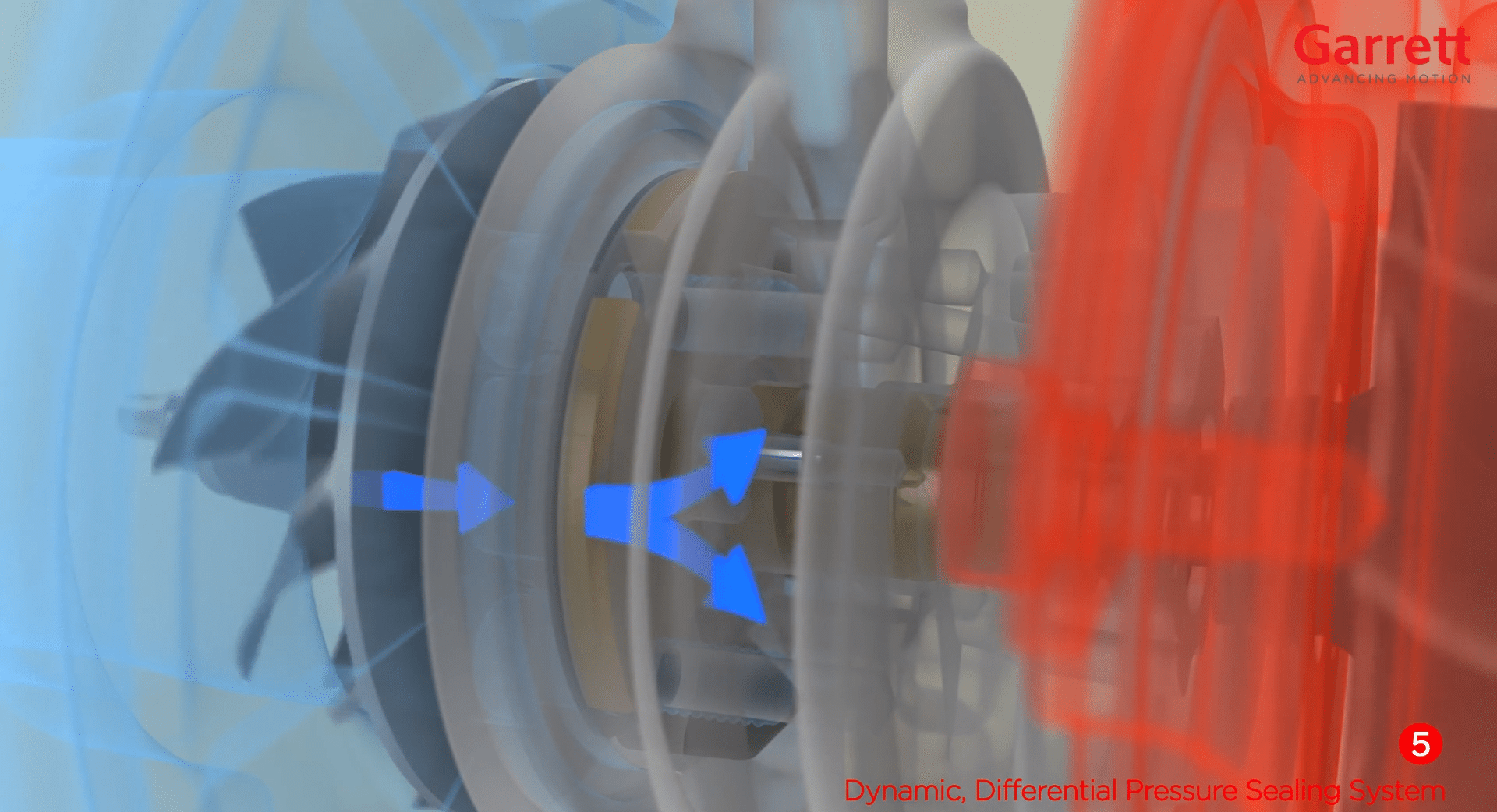

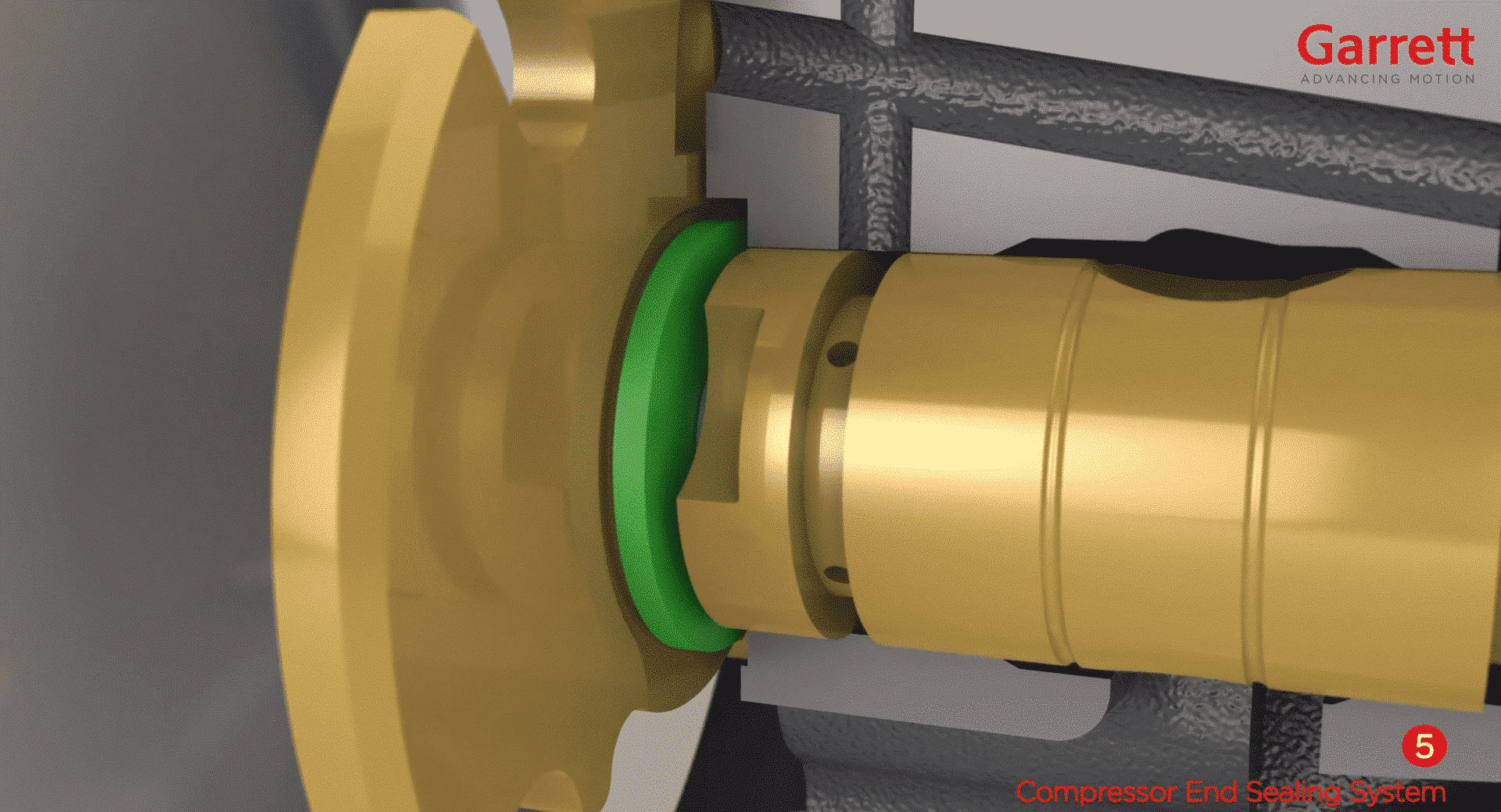

Compressor End Sealing System

At the compressor end, the sealing system is more complex and there are many different designs to work with specific turbo models and applications.

As the oil finishes its work in the journal bearing, it spills out and is thrown outwards under centrifugal force by the back face of the thrust collar, whilst the oil from the thrust bearing is also thrown outwards by the rotating thrust collar where it again drops down under gravity to be collected by the oil drain. The thrust collar may be a simple disc, or it may be a combined thrust collar incorporating an oil/air separator and thrust spacer incorporating one, two or even three piston rings depending on the application for the turbo.

Svenska

Svenska

English

English